The Best 3d Printer Filaments Including Petg And Also Pla 3d Printer F…

페이지 정보

본문

PLA is stronger as well as stiffer than abdominal muscle, yet bad heat-resistance properties means PLA is primarily an enthusiast material. ABS is weaker and also less inflexible, however also tougher as well as lighter, making it a much better plastic for prototyping applications.

An instance material is extruding jelly right into a Ca2+ storage tank for microvasculature. For other products such as TCP, a remedy is made with water, extruded from a syringe, and afterwards lyophilized to remove the fluid. In the Star Trip tv collection, one of the numerous futuristic devices included was the replicator, a device about the size of a microwave. It might produce anything on demand-- from a dry martini to a bowl of hen soup. But while that was from an imaginary globe centuries right into the future, nowadays 3D printers are the closest thing we need to a real-life replicator.

However, when you warm the 3D prints, the amorphous structure rearranges itself to a crystalline type which makes such 3D. prints vulnerable to failure. If mouse click the up coming website part alignment is tough, you ought to utilize products that have a far better bonding propensity, as an example, PETG. Additionally, note that part orientation will influence the best of the print surface as well as the print expense due to the requirement for numerous products. PLA is a costly 3D printing material ideal for prints with heavy usage as well as high resolution. It has a tensile strength of 7250 psi however will certainly deteriorate on exposure to light. These are immensely handy for eliminating assistance material, for making a great, clean cut when cutting filament prior to packing, and also snipping off any flaws on your 3D prints.

However, when you warm the 3D prints, the amorphous structure rearranges itself to a crystalline type which makes such 3D. prints vulnerable to failure. If mouse click the up coming website part alignment is tough, you ought to utilize products that have a far better bonding propensity, as an example, PETG. Additionally, note that part orientation will influence the best of the print surface as well as the print expense due to the requirement for numerous products. PLA is a costly 3D printing material ideal for prints with heavy usage as well as high resolution. It has a tensile strength of 7250 psi however will certainly deteriorate on exposure to light. These are immensely handy for eliminating assistance material, for making a great, clean cut when cutting filament prior to packing, and also snipping off any flaws on your 3D prints.

PLA is a fantastic first product to make use of as you are learning more about 3D printing since it is simple to publish, really low-cost, and produces parts that can be used for a variety of applications. It is likewise one of one of the most environmentally friendly filaments on the marketplace today.

The LulzBot Mini 2 is a great option for individuals, institutions, as well as recreation center thanks to its easy setup and procedure. Hobbyists and tinkerers will like its ability to publish with a wide range of filament kinds. PLA is normally the very first filament utilized by beginners to 3D printing, as it is anticipated to have fairly foreseeable outcomes. Nonetheless, the quality of PLA may vary relying on the producer. Also filaments from the exact same supplier but of different shades may have different printing properties.

Timber 3d Printer Filaments Composite Filaments

Sign up for our newsletter to get updates on new Creality 3D printers, deals, and also brand-new posts. Advance PLA is available in numerous colors, and has a hassle-free sign demonstrating how much filament is left on the roll. Right here is a video that evaluates the durability and also stamina of both completely dry and oiled worm equipments made from PLA, PETG and also ABS, at high speeds.

Sunlu additionally ranks their PLA 3D filament as up to five times more powerful than typical PLAs. In contrast to PLA, PETG has actually enhanced high temperature resistance, stamina with some versatility, as well as a glossy look. In comparison to ABS, PETG is a lot easier to publish-- the only giving in that you need to make is to publish it a lot more gradually than PLA. Polycarbonate and also Nylon appear to be the best filaments for 3D printing gears in the house, because of their toughness as well as strength. Nonetheless, Nylon is far more available and versatile, which is why it is typically considered as the most effective filament, since even more people utilize it. As most made use of and finest 3D printer filaments, ABS-- Acrylonitrile Butadiene Styrene as well as PLA-- Polylactic Acid is the key choices for the majority of the 3D printing organizations.

Soft PLA, additionally known as 'flexible' PLA, serves for publishing rubber-like parts that can flex or bend. Best utilized for challenging useful components, use components, as well as production-ready prints. Low-odor as well as very easy to publish like PLA, yet high heat resistance like abdominal. PRO Collection PLA filament is a difficult but breakable material with a large selection of abundant shades. Common 3D prints with abdominal muscle are Interlocking components like equipments, components subjected to UV and warm like a vehicle cup holder, or prototyping.

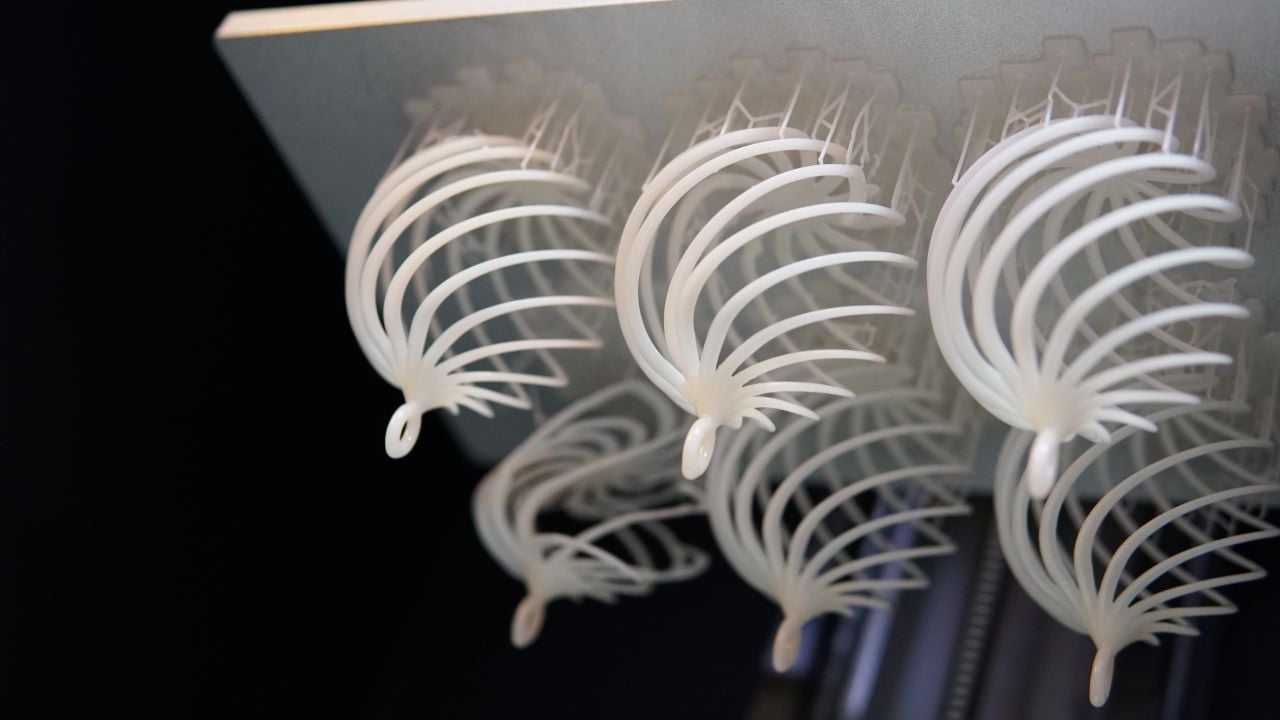

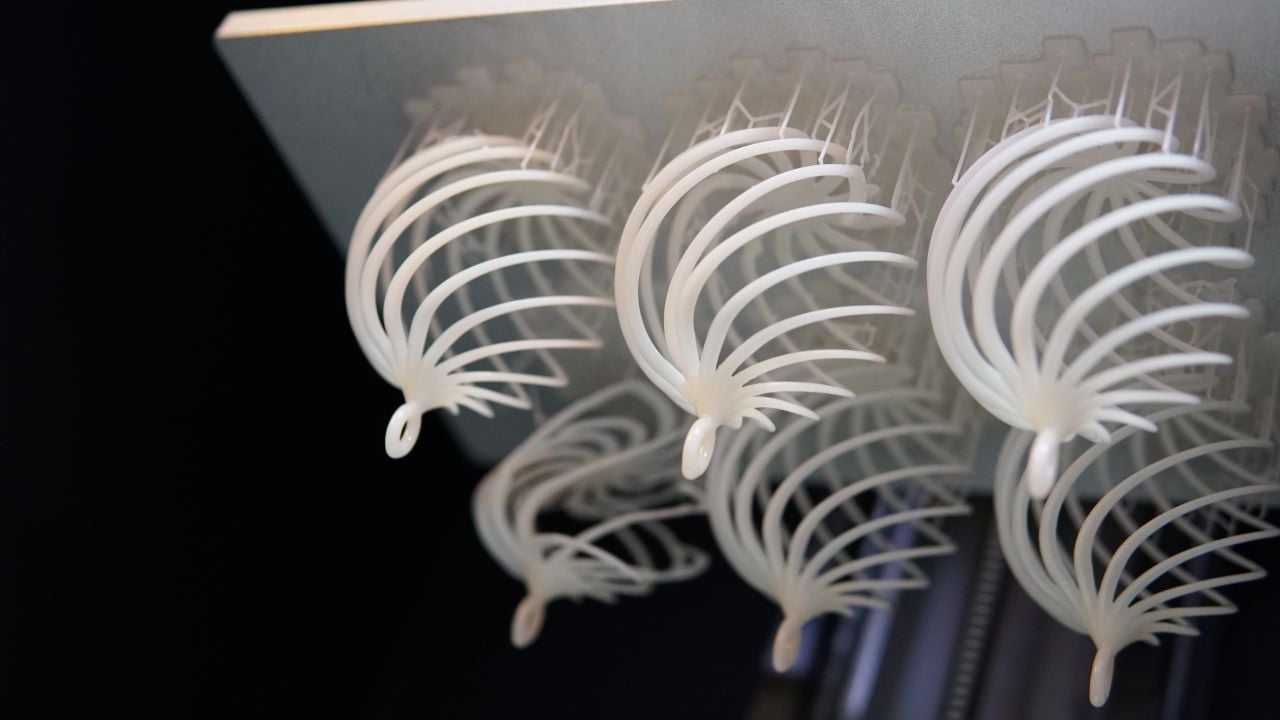

Among the main objectives of post-processing is to enhance the look of published objects. For instance, the FDM 3D printing procedure creates visible layer lines on the surface of components, interfering with their total aesthetic top quality. However post-processing techniques such as sanding, brightening, and painting can effectively get rid of or lessen these lines, leading to a smoother and much more professional-looking surface. In 2003, Rupert Soar secured funding and also formed the freeform building and construction team at Loughborough College, UK, 3D Prototyping Essentials to check out the potential for up-scaling existing 3D Design and Innovation printing strategies for building applications. In 2005, the group safeguarded funding to construct a large construction 3D printing machine utilizing 'off the shelf' elements to check out just how complicated such components could be and reasonably satisfy the demands for building and construction.

At the time, virtually seven out of 10 respondents attested using 3D printing for this objective. No other choice also came close in popularity; only three in ten chosen the runner-up. Nanoscale 3D printing-- in other words 3D printing of objects that are a simply couple of billionths of a meter in dimension-- opens fantastic possibilities, the chemist clarifies.

Shredders And Also Filament Extruders: Reusing Stopped Working Or Old Prints As Well As Filament

In the indirect method, molds are published utilizing commercially available plaster powder, as well as naturally degradable polymers are cast right into the printed mold and mildew. Several products can be cast under the comparable printing process parameters, whereas private process parameters need to be maximized to optimize the construct resolution in a traditional direct 3DP strategy. This modern technology might be put on treat individuals with zygomatic bone cracks.

An instance material is extruding jelly right into a Ca2+ storage tank for microvasculature. For other products such as TCP, a remedy is made with water, extruded from a syringe, and afterwards lyophilized to remove the fluid. In the Star Trip tv collection, one of the numerous futuristic devices included was the replicator, a device about the size of a microwave. It might produce anything on demand-- from a dry martini to a bowl of hen soup. But while that was from an imaginary globe centuries right into the future, nowadays 3D printers are the closest thing we need to a real-life replicator.

However, when you warm the 3D prints, the amorphous structure rearranges itself to a crystalline type which makes such 3D. prints vulnerable to failure. If mouse click the up coming website part alignment is tough, you ought to utilize products that have a far better bonding propensity, as an example, PETG. Additionally, note that part orientation will influence the best of the print surface as well as the print expense due to the requirement for numerous products. PLA is a costly 3D printing material ideal for prints with heavy usage as well as high resolution. It has a tensile strength of 7250 psi however will certainly deteriorate on exposure to light. These are immensely handy for eliminating assistance material, for making a great, clean cut when cutting filament prior to packing, and also snipping off any flaws on your 3D prints.

However, when you warm the 3D prints, the amorphous structure rearranges itself to a crystalline type which makes such 3D. prints vulnerable to failure. If mouse click the up coming website part alignment is tough, you ought to utilize products that have a far better bonding propensity, as an example, PETG. Additionally, note that part orientation will influence the best of the print surface as well as the print expense due to the requirement for numerous products. PLA is a costly 3D printing material ideal for prints with heavy usage as well as high resolution. It has a tensile strength of 7250 psi however will certainly deteriorate on exposure to light. These are immensely handy for eliminating assistance material, for making a great, clean cut when cutting filament prior to packing, and also snipping off any flaws on your 3D prints.PLA is a fantastic first product to make use of as you are learning more about 3D printing since it is simple to publish, really low-cost, and produces parts that can be used for a variety of applications. It is likewise one of one of the most environmentally friendly filaments on the marketplace today.

The LulzBot Mini 2 is a great option for individuals, institutions, as well as recreation center thanks to its easy setup and procedure. Hobbyists and tinkerers will like its ability to publish with a wide range of filament kinds. PLA is normally the very first filament utilized by beginners to 3D printing, as it is anticipated to have fairly foreseeable outcomes. Nonetheless, the quality of PLA may vary relying on the producer. Also filaments from the exact same supplier but of different shades may have different printing properties.

Timber 3d Printer Filaments Composite Filaments

Sign up for our newsletter to get updates on new Creality 3D printers, deals, and also brand-new posts. Advance PLA is available in numerous colors, and has a hassle-free sign demonstrating how much filament is left on the roll. Right here is a video that evaluates the durability and also stamina of both completely dry and oiled worm equipments made from PLA, PETG and also ABS, at high speeds.

Sunlu additionally ranks their PLA 3D filament as up to five times more powerful than typical PLAs. In contrast to PLA, PETG has actually enhanced high temperature resistance, stamina with some versatility, as well as a glossy look. In comparison to ABS, PETG is a lot easier to publish-- the only giving in that you need to make is to publish it a lot more gradually than PLA. Polycarbonate and also Nylon appear to be the best filaments for 3D printing gears in the house, because of their toughness as well as strength. Nonetheless, Nylon is far more available and versatile, which is why it is typically considered as the most effective filament, since even more people utilize it. As most made use of and finest 3D printer filaments, ABS-- Acrylonitrile Butadiene Styrene as well as PLA-- Polylactic Acid is the key choices for the majority of the 3D printing organizations.

Soft PLA, additionally known as 'flexible' PLA, serves for publishing rubber-like parts that can flex or bend. Best utilized for challenging useful components, use components, as well as production-ready prints. Low-odor as well as very easy to publish like PLA, yet high heat resistance like abdominal. PRO Collection PLA filament is a difficult but breakable material with a large selection of abundant shades. Common 3D prints with abdominal muscle are Interlocking components like equipments, components subjected to UV and warm like a vehicle cup holder, or prototyping.

Among the main objectives of post-processing is to enhance the look of published objects. For instance, the FDM 3D printing procedure creates visible layer lines on the surface of components, interfering with their total aesthetic top quality. However post-processing techniques such as sanding, brightening, and painting can effectively get rid of or lessen these lines, leading to a smoother and much more professional-looking surface. In 2003, Rupert Soar secured funding and also formed the freeform building and construction team at Loughborough College, UK, 3D Prototyping Essentials to check out the potential for up-scaling existing 3D Design and Innovation printing strategies for building applications. In 2005, the group safeguarded funding to construct a large construction 3D printing machine utilizing 'off the shelf' elements to check out just how complicated such components could be and reasonably satisfy the demands for building and construction.

At the time, virtually seven out of 10 respondents attested using 3D printing for this objective. No other choice also came close in popularity; only three in ten chosen the runner-up. Nanoscale 3D printing-- in other words 3D printing of objects that are a simply couple of billionths of a meter in dimension-- opens fantastic possibilities, the chemist clarifies.

Shredders And Also Filament Extruders: Reusing Stopped Working Or Old Prints As Well As Filament

In the indirect method, molds are published utilizing commercially available plaster powder, as well as naturally degradable polymers are cast right into the printed mold and mildew. Several products can be cast under the comparable printing process parameters, whereas private process parameters need to be maximized to optimize the construct resolution in a traditional direct 3DP strategy. This modern technology might be put on treat individuals with zygomatic bone cracks.

- 이전글Five Psychiatrist Nearme Lessons From The Professionals 23.11.28

- 다음글Bang Om Sokken Kwijt te Raken? 23.11.28

댓글목록

등록된 댓글이 없습니다.